Plastic injection, Micro-mechanics, Vibrating bowls : a 3 dimensional solution

From its 1964 inception, Roland Bailly SAS has remained an independent force of

continuing innovation, and one that has responded to the changing needs of industry

while remaining true to its original ethos.

Thanks to a valued and highly-skilled workforce, absolute priority can be given to

achieving complete client satisfaction.

With a strong team of qualified engineers, specialist fabrication workshops, and a

dedicated Research and Development unit, the company has a loyal international

client base across a wide range of technologies and insdustries, ranging from :

automotive, telecommunications, aerospace, optical eye-wear, watch, clock making

and jewelry, electrical appliances, connectics, and medicine.

Our staff speak English, German and Spanish, to better facilitate communication of

ideas, concepts, and design criteria as efficiently as possible.

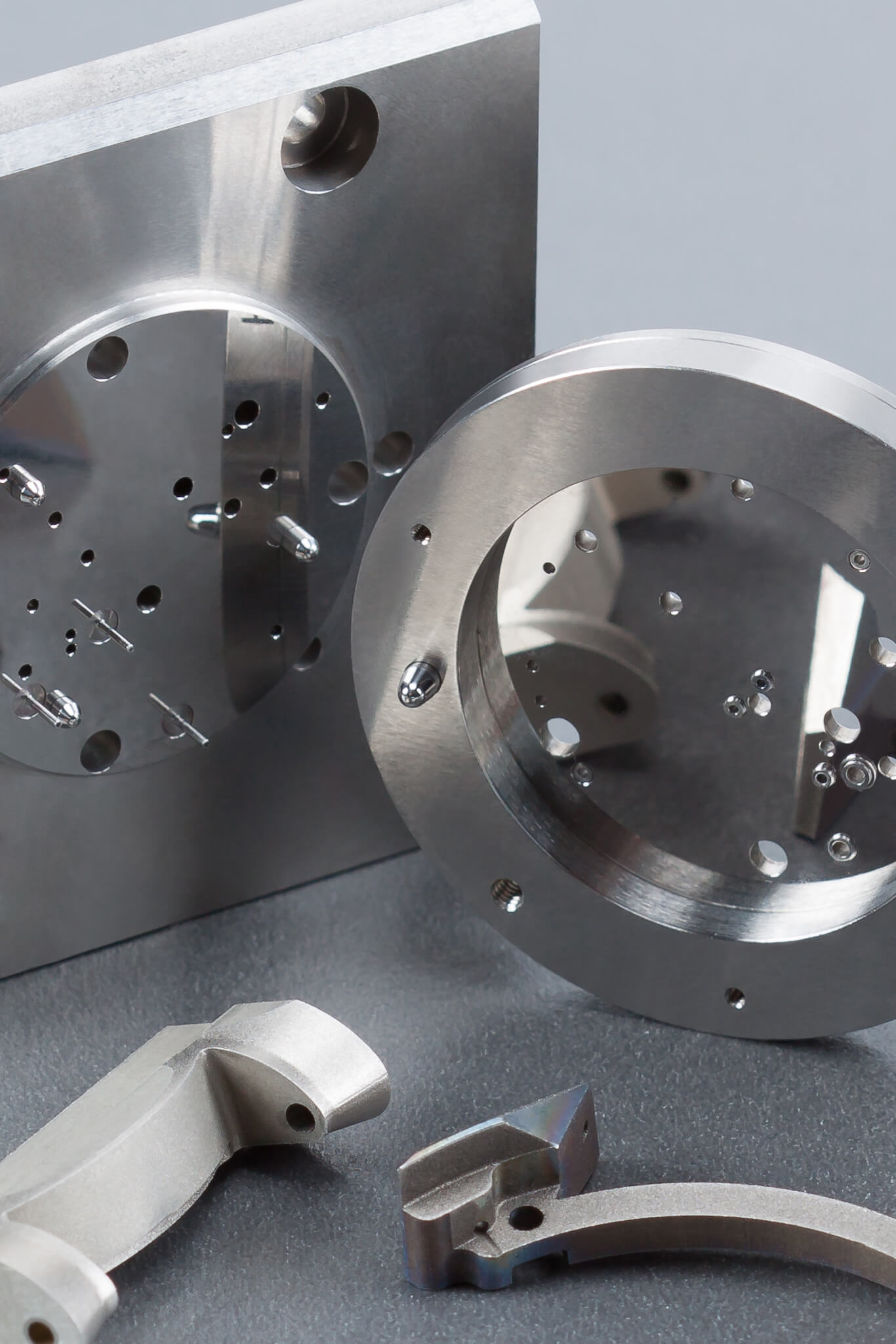

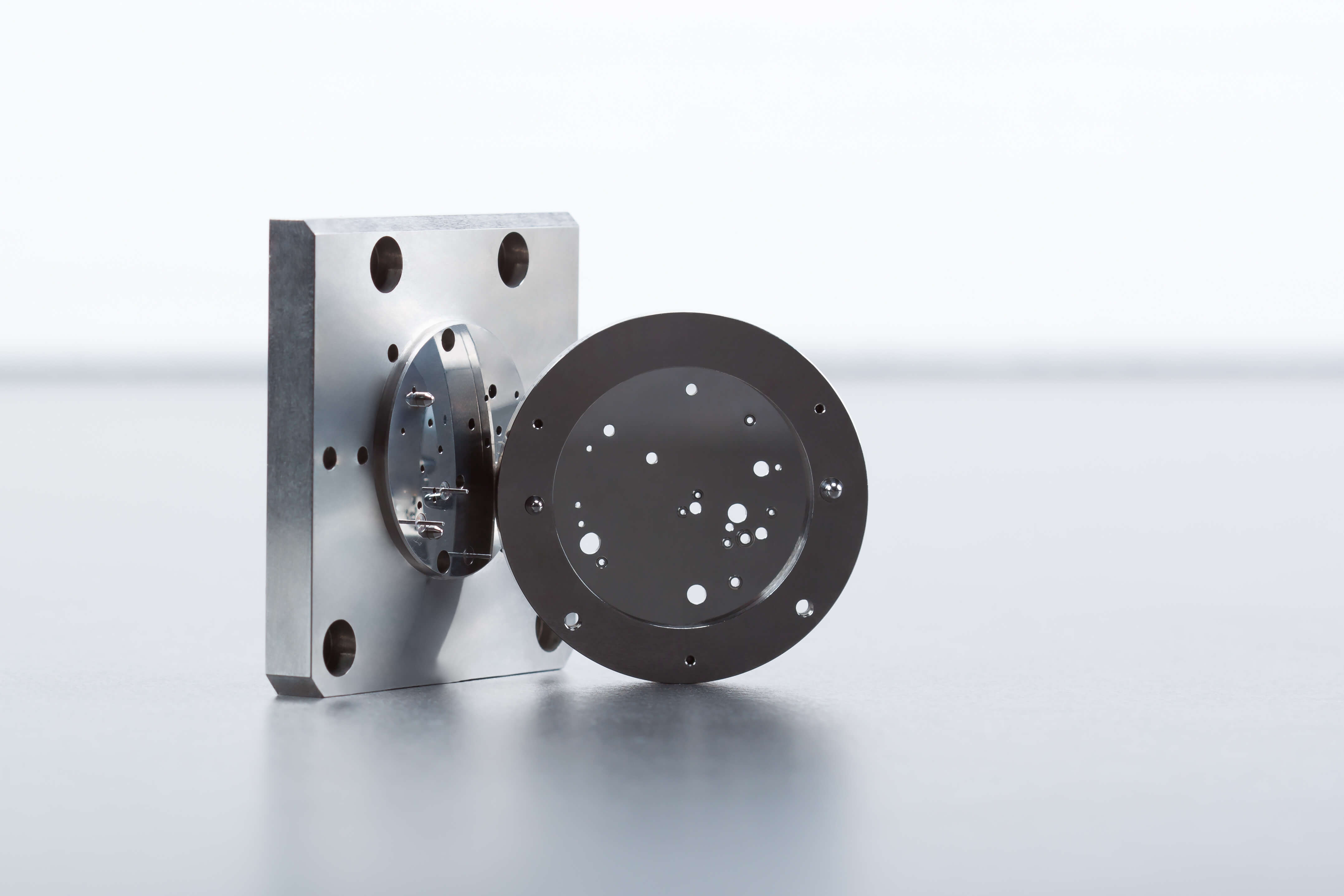

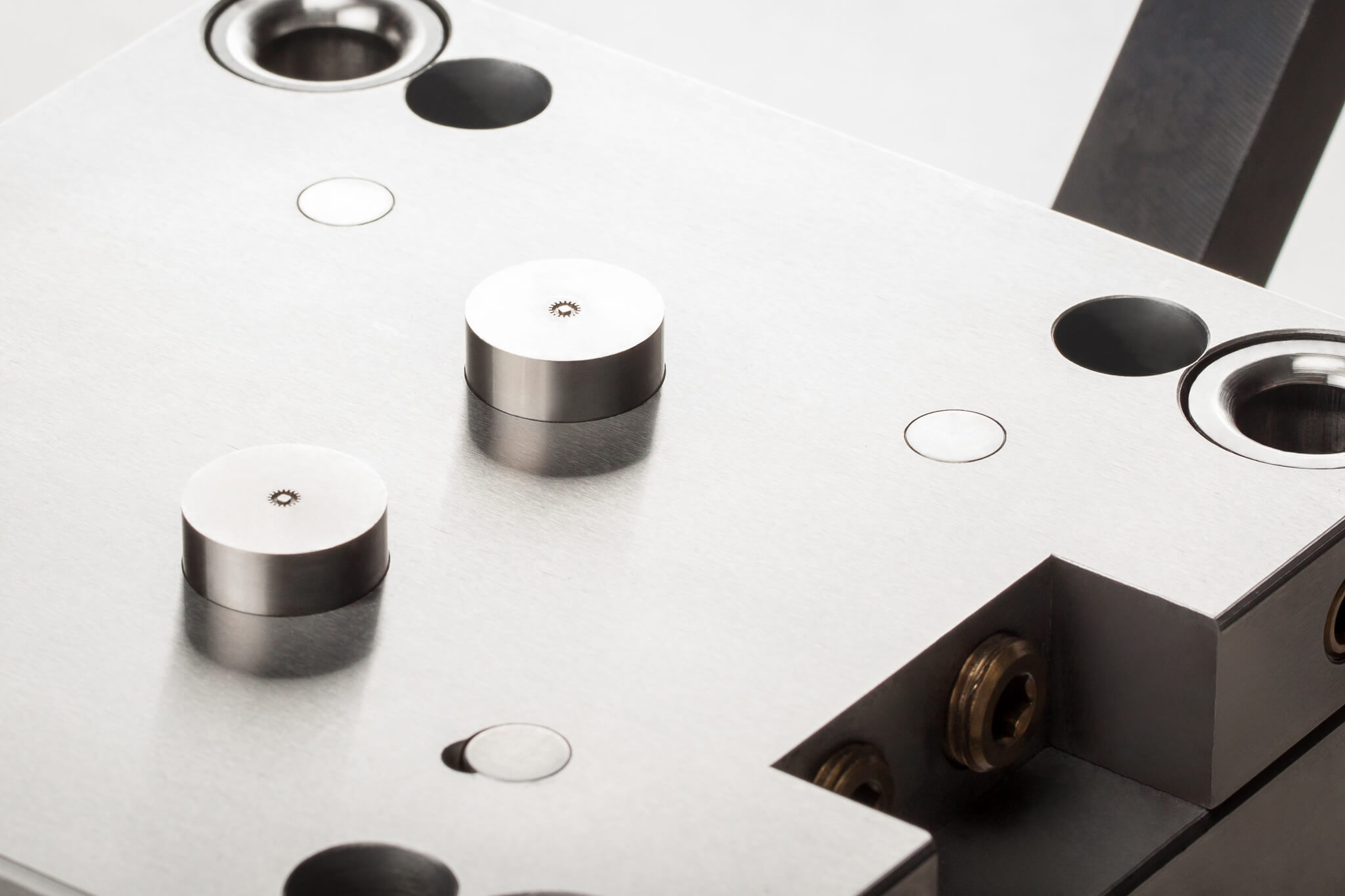

At the heart of the three fabrication departments - Vibration, Tooling and Micro Injection - the company creates high precision injection moulds, complex mechanical

parts, vibrating feeder bowls, centrifuge feeders and conveyors.

A "Manufacture of Solutions" Roland Bailly SAS has acquired a certain notoriety

within the industry through its development of a method to produce plastic components in 3 dimensions.

Roland Bailly SAS is certified according to : ISO 9001 v2015, for all production output since 2000.